Commercial Bumper Pool Tables

Featuring our exclusive PermaCup™

Price Options:

Only $2,695

(plus crating/freight)

Only $2,695

(plus crating/freight)

Commercial Tables - Features & Benefits

Since you’re on this page, I assume you have a need for a commercial bumper pool table. As you will see, they are not equal. Just because a table is labeled or looks “commercial” does not make it one. Unless you’ve run a game room before, you are probably not aware that problems even exist but I can assure you that not only are they real, they will make you sorry you even bought one.

Over two decades ago, a Boys & Girls Club director was complaining to me that , as much as his kids loved playing bumper pool, he couldn’t find a game that could stand up to the “hard play” found in the clubs. Even the so called “commercial” games were found less than adequate. Here’s a list of problems found on every bumper pool table made and how we resolved them.

Bumper Posts

A bumper pool table has 12 obstacles that the players must shoot around. These obstacles are called “posts”. Attached to each post is a rubber ring called a “bumper”. The entire unit is called a “bumper post”. Virtually all other posts are made of either wood or plastic and the rubber ring attaches by sliding the ring down from the top of the post. Inserted into the bottom of the post is a metal rod that slides through a hole in the slate and is secured by a washer and nut.

Since you’re on this page, I assume you have a need for a commercial bumper pool table. As you will see, they are not equal. Just because a table is labeled or looks “commercial” does not make it one. Unless you’ve run a game room before, you are probably not aware that problems even exist but I can assure you that not only are they real, they will make you sorry you even bought one.

Over two decades ago, a Boys & Girls Club director was complaining to me that , as much as his kids loved playing bumper pool, he couldn’t find a game that could stand up to the “hard play” found in the clubs. Even the so called “commercial” games were found less than adequate. Here’s a list of problems found on every bumper pool table made and how we resolved them.

Bumper Posts

A bumper pool table has 12 obstacles that the players must shoot around. These obstacles are called “posts”. Attached to each post is a rubber ring called a “bumper”. The entire unit is called a “bumper post”. Virtually all other posts are made of either wood or plastic and the rubber ring attaches by sliding the ring down from the top of the post. Inserted into the bottom of the post is a metal rod that slides through a hole in the slate and is secured by a washer and nut.

The Problem - In a commercial environment (such as a Boys & Girls Club) because the rubber ring slides down from the top of the post, the kids can easily peel off the rubber ring (and play ring frisbee) and then they shoot the balls into the unprotected post and break them. The club must maintain a large supply of replacement rubber rings and bumper posts just to keep the game operational. Many become so frustrated that they remove the game from the room.

Our Solution - You just don’t run down to the bumper post store and select the best post that resolves these problems. We have to have them manufactured to our specifications. Our posts are made of solid machined steel with a large mushroom top that prevents the rubber ring from being removed from the top. To put a rubber ring on our post requires rolling on the ring from the bottom of the post (with some effort). But we didn’t stop there. Over time due to the vibration of the ball constantly hitting the bumper post, they can loosen up to the point that the kids can take them off (and take off with them in their pocket). To prevent this, we insert a 3/8” metal rod (rather than the usual 3/16ths others use) and secure it using a special flexible washer that greatly reduces the chance of the post loosing up. Until recently, if in the unlikely event our post became loose, they could be removed from the game (and probably the building). Due to the substantially higher replacement cost of our posts, we have now modified the post with a ring attached to the bottom of the threaded insert which, even if the post became loose, will prevent the post from being removed from the table. However, it is still good preventive maintenance to check all posts at least once a year.

Ball Cup

At each end of a bumper pool table is a hole that the players are trying to shoot their balls into. When the slate is covered the cloth that covers each hole must be cut many times to allow a plastic ring to be inserted into the cup hole. The reason for the cup is to protect the high wear area around the hole and to hide (and protect) the cloth tabs that were cut in the cloth.

The Problem - Every other table made in the world uses the same plastic cup liner….. Except Us! Because of the different thickness of cloth and the complete lack of the slate companies ability to hold a good tolerance in the holes they drill, the only way to try and secure the cup is to wrap tape around the outside of the cup and then pound the cup down into the hole. This works fine for a home table but is completely inadequate for a game in a commercial environment. What happens is that the kids jam the butt of the cue into the hole which loosens the cup and allows them to remove it. Then the real fun starts. With the protective cup removed, the kids then have access to the cut cloth tabs and they grab the small tabs and rip the cloth out into the playfield which makes the game impossible to play and requires the club to make another substantial investment in getting the game recovered. Even once it’s recovered, the same plastic cups are put back into the holes (albeit with a bit more tape) and the process starts all over again.

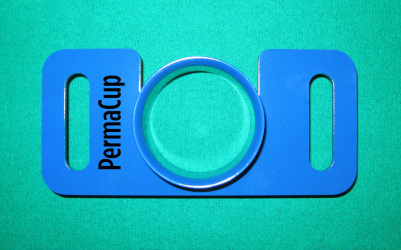

Our Solution - Years ago we thought we had this problem resolved. We manufactured a metal cup with a metal locking ring to keep it in place. To be fair, it survived longer than a regular plastic cup but in the end it also failed. Finally we have managed to end this problem with our simple and effective PermaCup™. The PermaCup™ consists of two pieces; a metal base and metal cup. Simply push the metal cup through the hole in the slate, slide the metal base into the recess in the cup, align the base with the bumper post threaded studs and tighten.

Additional Improvements

Large Metal Corner Castings - We use commercial metal corner castings on our tables. These castings allow us to bolt the casting down to the rails using two large bolts. All other companies use a small metal corner (on both home and commercial models) that uses only one small bolt (or a couple of screws)to hold in place. Over time these become loose and the kids either twist the corner which either breaks or bends out of shape or the rail wood breaks apart. These smaller castings work fine on home tables (we even use them ourselves) but they have no business on commercial tables. See Picture

Cushions - We use the same square nose cushions found on $10,000 English Snooker tables. They provide consistent rebounding and by design, provide a much larger gluing area to adhere to the rail.

Rails/Cabinet/Legs - Our rails are 5” wide solid hardwood. Many other tables are made from particle wood or medium density fiberboard (MDF). These two rails breakdown, split, or expand when wet. Our rails also bolt down to the table like a normal pool table while the rails on most other commercial tables use either nails or screws to attach the rails to the table.

Our cabinet is ¾” plywood with a hardwood base frame permanently attached. Our legs are a combination of hardwood/plywood. Then, the entire table (rails, cabinet, legs) is covered with high pressure laminate which is more burn, stain and scratch resistant than almost any other material. Because of the many advantages, high pressure laminate is used on all rails of commercial tables but many times, particle wood, mdf, or melamine (which is particle wood with colored paper over it) is used in the cabinet and legs. Again, our table is 100% high pressure laminate

Return on Investment

OR

How I Can Justify This To My Boss

The problems I listed above, aren’t something I made up just to scare you. They are real, ongoing issues that, as a game room operator, you will have to deal with on a daily basis. And, every other bumper pool table made in the world have these issues built into them. Game manufacturers just build games for the masses. Sure, some will throw on a little extra metal trim and call it “commercial” but they really don’t care about you guys. You’re much too small a portion of the pie to warrant the investment into research and development. But to a small manufacturer like us, you represent a good portion of our business, and to give you some idea of how seriously we take this, we spend more money just on protective trim, cushions, bumper posts and protective ball cups than everyone else does building their entire table.

I would normally not be so brazen as to suggest this, but it really is the truth. If you can’t afford/justify our table, you are just throwing away money buying something else. Simply put, you’d be far better off not even having a bumper pool table.

The first way the table begins to payback is in recovery costs. With our new Permacup ball cups, the cloth tabs aren’t exposed which means the cloth can’t easily be ripped and since playing bumper pool is far easier on the cloth than a regular table, the cloth will probably last 2-3x longer than pool table cloth. With every other table, as soon as the kids figure out how to remove the plastic ball cup your cloth will be ripped. It might not be the moment you put the table in, but to borrow a line from Casablanca, “maybe not today or tomorrow, but soon and for the rest of your life.”

The next payback is in replacement rubber rings and posts. It really isn’t the actual expense of the replacement parts, it’s the aggravation of having to do so. I had a booth at a Boys & Girls convention and an Executive Director stopped by and told me that his kids just love bumper pool (he had four of them) but he got to the point that replacing parts was driving him so crazy, he finally took them all off the floor and locked them in another room.

Another payback is part problem and part solution. If you’re a non-profit organization like B&GC’s, appearance is an issue. It doesn’t reflect well on you (or the club) for a parent to see some beat up bumper pool table with torn cloth. However, it might work to your benefit if you’re hosting a fund raising event in the club. All of you have “wish lists” and you might just get lucky and have a good supporter buy one for you.

Finally, purchasing our bumper pool table, gets you off the “purchase, repair, replace” merry-go-round that many of you are constantly on. Your patrons gladly donate money to you - but you also have a responsibility to them to spend it wisely.

In my business, we use portable drills all the time. The drills I buy are about 2-3x the cost of a normal drill. But I have no problem spending the money because they don’t break when dropped, are more powerful, recharge faster and have a host of other advantages - they also last a lot longer. Daily, I still use two drills I’ve had over 20 years. In other words, they do the job they were specifically designed for, and that’s what our bumper pool tables will do for you.

Our Solution - You just don’t run down to the bumper post store and select the best post that resolves these problems. We have to have them manufactured to our specifications. Our posts are made of solid machined steel with a large mushroom top that prevents the rubber ring from being removed from the top. To put a rubber ring on our post requires rolling on the ring from the bottom of the post (with some effort). But we didn’t stop there. Over time due to the vibration of the ball constantly hitting the bumper post, they can loosen up to the point that the kids can take them off (and take off with them in their pocket). To prevent this, we insert a 3/8” metal rod (rather than the usual 3/16ths others use) and secure it using a special flexible washer that greatly reduces the chance of the post loosing up. Until recently, if in the unlikely event our post became loose, they could be removed from the game (and probably the building). Due to the substantially higher replacement cost of our posts, we have now modified the post with a ring attached to the bottom of the threaded insert which, even if the post became loose, will prevent the post from being removed from the table. However, it is still good preventive maintenance to check all posts at least once a year.

Ball Cup

At each end of a bumper pool table is a hole that the players are trying to shoot their balls into. When the slate is covered the cloth that covers each hole must be cut many times to allow a plastic ring to be inserted into the cup hole. The reason for the cup is to protect the high wear area around the hole and to hide (and protect) the cloth tabs that were cut in the cloth.

The Problem - Every other table made in the world uses the same plastic cup liner….. Except Us! Because of the different thickness of cloth and the complete lack of the slate companies ability to hold a good tolerance in the holes they drill, the only way to try and secure the cup is to wrap tape around the outside of the cup and then pound the cup down into the hole. This works fine for a home table but is completely inadequate for a game in a commercial environment. What happens is that the kids jam the butt of the cue into the hole which loosens the cup and allows them to remove it. Then the real fun starts. With the protective cup removed, the kids then have access to the cut cloth tabs and they grab the small tabs and rip the cloth out into the playfield which makes the game impossible to play and requires the club to make another substantial investment in getting the game recovered. Even once it’s recovered, the same plastic cups are put back into the holes (albeit with a bit more tape) and the process starts all over again.

Our Solution - Years ago we thought we had this problem resolved. We manufactured a metal cup with a metal locking ring to keep it in place. To be fair, it survived longer than a regular plastic cup but in the end it also failed. Finally we have managed to end this problem with our simple and effective PermaCup™. The PermaCup™ consists of two pieces; a metal base and metal cup. Simply push the metal cup through the hole in the slate, slide the metal base into the recess in the cup, align the base with the bumper post threaded studs and tighten.

Additional Improvements

Large Metal Corner Castings - We use commercial metal corner castings on our tables. These castings allow us to bolt the casting down to the rails using two large bolts. All other companies use a small metal corner (on both home and commercial models) that uses only one small bolt (or a couple of screws)to hold in place. Over time these become loose and the kids either twist the corner which either breaks or bends out of shape or the rail wood breaks apart. These smaller castings work fine on home tables (we even use them ourselves) but they have no business on commercial tables. See Picture

Cushions - We use the same square nose cushions found on $10,000 English Snooker tables. They provide consistent rebounding and by design, provide a much larger gluing area to adhere to the rail.

Rails/Cabinet/Legs - Our rails are 5” wide solid hardwood. Many other tables are made from particle wood or medium density fiberboard (MDF). These two rails breakdown, split, or expand when wet. Our rails also bolt down to the table like a normal pool table while the rails on most other commercial tables use either nails or screws to attach the rails to the table.

Our cabinet is ¾” plywood with a hardwood base frame permanently attached. Our legs are a combination of hardwood/plywood. Then, the entire table (rails, cabinet, legs) is covered with high pressure laminate which is more burn, stain and scratch resistant than almost any other material. Because of the many advantages, high pressure laminate is used on all rails of commercial tables but many times, particle wood, mdf, or melamine (which is particle wood with colored paper over it) is used in the cabinet and legs. Again, our table is 100% high pressure laminate

Return on Investment

OR

How I Can Justify This To My Boss

The problems I listed above, aren’t something I made up just to scare you. They are real, ongoing issues that, as a game room operator, you will have to deal with on a daily basis. And, every other bumper pool table made in the world have these issues built into them. Game manufacturers just build games for the masses. Sure, some will throw on a little extra metal trim and call it “commercial” but they really don’t care about you guys. You’re much too small a portion of the pie to warrant the investment into research and development. But to a small manufacturer like us, you represent a good portion of our business, and to give you some idea of how seriously we take this, we spend more money just on protective trim, cushions, bumper posts and protective ball cups than everyone else does building their entire table.

I would normally not be so brazen as to suggest this, but it really is the truth. If you can’t afford/justify our table, you are just throwing away money buying something else. Simply put, you’d be far better off not even having a bumper pool table.

The first way the table begins to payback is in recovery costs. With our new Permacup ball cups, the cloth tabs aren’t exposed which means the cloth can’t easily be ripped and since playing bumper pool is far easier on the cloth than a regular table, the cloth will probably last 2-3x longer than pool table cloth. With every other table, as soon as the kids figure out how to remove the plastic ball cup your cloth will be ripped. It might not be the moment you put the table in, but to borrow a line from Casablanca, “maybe not today or tomorrow, but soon and for the rest of your life.”

The next payback is in replacement rubber rings and posts. It really isn’t the actual expense of the replacement parts, it’s the aggravation of having to do so. I had a booth at a Boys & Girls convention and an Executive Director stopped by and told me that his kids just love bumper pool (he had four of them) but he got to the point that replacing parts was driving him so crazy, he finally took them all off the floor and locked them in another room.

Another payback is part problem and part solution. If you’re a non-profit organization like B&GC’s, appearance is an issue. It doesn’t reflect well on you (or the club) for a parent to see some beat up bumper pool table with torn cloth. However, it might work to your benefit if you’re hosting a fund raising event in the club. All of you have “wish lists” and you might just get lucky and have a good supporter buy one for you.

Finally, purchasing our bumper pool table, gets you off the “purchase, repair, replace” merry-go-round that many of you are constantly on. Your patrons gladly donate money to you - but you also have a responsibility to them to spend it wisely.

In my business, we use portable drills all the time. The drills I buy are about 2-3x the cost of a normal drill. But I have no problem spending the money because they don’t break when dropped, are more powerful, recharge faster and have a host of other advantages - they also last a lot longer. Daily, I still use two drills I’ve had over 20 years. In other words, they do the job they were specifically designed for, and that’s what our bumper pool tables will do for you.